Click to Download the PDF

Download the Word Doc

President’s Message

Welcome to the January, 2022 edition of the Georgina Historical Society newsletter. Hopefully, you were able to spend some time with your family and friends over the Holiday Season. It was certainly very enjoyable to see so many of you at our annual meeting in November and at that time we were very optimistic that we would be returning to our normal Georgina Historical Society meetings and events in the New Year. Unfortunately the appearance and spread of the Omicron variant of the Covid virus has once again put things on hold and this January newsletter was delayed due to this uncertainty. The spread seems to be flattening and hopefully we can, once again, plan and inform you of Historical Society happenings and events. We have certainly been living through an historical event!

If you are looking for something to do during these long winter days and nights, I would in encourage you do your own research on past winter activities in Georgina and let us know of any interesting stories you discover. Early ice fishing, the ice industry, harness horse racing on the lake, the lumber industry, maple syrup making, social activities of our ancestors during the long winter days and nights, travel during the winter , etc.; all have interesting histories, stories and anecdotes. Please share any tales or stories you find with your Historical Society members.

It is not to late to purchase a 2022 Georgina Historical Society calendar. Contact me or any board member to purchase your calendar. The $15 purchase price goes to support the refurbishing of the caboose and other GHS projects.

Stay well and be safe; thank you.

Tom Glover, President

Counting down the Hours until Lunchtime – The Schoolhouse Bell – By Sarah Harrison

Schoolhouses (such as the one at Cedarbrae) would have bells on the roof of the building to let children know when school was in session. This recently refurbished bell is not original to the schoolhouse, but is fairly close to the one which would have resided in the bell tower. The bell has been painted grey, while the tower itself has been painted white so that it can be easily seen from the ground. Lettering on one side of the bell reads “No.24 Yoke”; this refers to the particular model of bell that was produced by the bell foundry. On the other side is the foundry stamp, reading “C.S. BELL & CO HILLSBORO O”. The way in which the stamp is written on the bell tells us that it was made in between 1882 – 1894.

Cedar Brae School c.1970s with its original bell

The C.S. Bell Company was based out of Hillsboro, Ohio in the United States. The founder of the company was a man named Charles Singleton Bell (1829 – 1905), born in Maryland, and who was apprenticed to a metal founder in Pittsburgh, PA when he was fifteen. He moved to Hillsboro, and purchased a foundry in 1858 with a partner to make farming equipment. His company started to manufacture bells in 1875; these bells differed from others in that they were made from a `crystal metal` steel alloy and were cheap to manufacture. The first year of production showed an output of 1,000 units. By 1890, 20,000 units were being produced in fifteen different sizes. Upon the death of Charles Bell in 1905, the company was passed onto his son Charles E. Bell. They expanded the company to include the manufacture of other metal farm equipment, while still manufacturing about 1000 bells per year. The company still exists today, but no longer are involved in manufacture of bells.

This bell was obtained for the Georgina Pioneer Village from a local source. It came from a hotel called the Glenwood (or the Springwood) hotel in Jackson`s Point, which flourished in the 1880`s. The picture above shows the proper location of the bell on the roof of the hotel. The building was damaged in 1978, when a fire gutted the upper floor and left in a bad state. In December of that year, the bell tower was donated to the Georgina Pioneer Village & Archives and set atop the schoolhouse. In fall 2014 the wood of the bell tower had rotted and had threatened to make the bell topple, so the Village sent it away to get it repaired. The bell and the tower both have new paint, and the wood has been replaced with sturdier timbers.

Our Pioneer Ancestors

The following profile was excerpted from the Georgina Township section of The History of the County of York, Volume 2, by C. Blackett Robinson Publisher in 1885, p. 509

KENNETH CAMERON, lots 10 and n, concession 4, was formerly a commissioned officer in the 93rd (Sutherland) Highlands. He emigrated to Canada in 1838, and locating first in Toronto was there married to Mary Murray. He subsequently moved to the Township of Thora, Ontario County, and from there to Georgina, where by industry and hard work he has succeeded in accumulating a very comfortable property. He had ten children born to him, eight of whom are living and in good position.

Georgina and North Gwillimbury in 1851

The following is a descriptive snapshot of Georgina and North Gwillimbury we’d like to share from W. H. Smith’s Canada: Past Present and Future Volume Two published in I851 by Thomas Maclear in Toronto, found on pages 36 to 39.

“To the north, and a little east of Scott, is the township of Georgina, .which is bounded on the north by Lake Simcoe. This township contains a considerable portion of good land, and is well watered, but from its remote situation, it settles up but slowly. In eighteen hundred and forty-two, it contained five hundred and eighty six inhabitants, and in eighteen hundred and forty-five, there were two grist and three saw mills. In eighteen hundred and fifty, the population had increased to

nine hundred and forty-six, there were two grist and three saw mills as before ; and thirteen thousand bushels of wheat, eight thousand bushels of oats, three thousand bushels of peas, nine thousand bushels of potatoes, nine thousand bushels of turnips, eight thousand pounds of maple

sugar, two thousand pounds of wool, four thousand pounds of cheese, and four thousand pounds of butter were produced from the crop of eighteen hundred and forty-nine.

In the west of the township, near the Lake, is a village called Sutton, but better known as Bouchier s Mills. It is twenty-three miles from the Holland Landing, and contains a grist and saw mill, carding and fulling mill, tannery and Post Office ; and a new cloth factory is erecting. Lake Simcoe, which, from the facilities it affords to the settlers of the surrounding country for the transit of stores and produce, is of considerable importance, is the largest of the small lakes in Canada. In any other

country it would be considered a Lake of some magnitude, but here, compared to Ontario, Erie, Huron, and though last not least, the noble Superior, it is a mere fish-pond ; and not a bad fish-pond either, as trout, whitefish and maskelonge of fine quality are taken in it. Lake Simcoe in length, from the extremity of Cook s Bay to the Narrows is about twenty-eight miles, and in width about seventeen, in addition to which, Kempenfeldt Bay is about eight miles in length, which will give the entire width of the Lake at twenty-five miles. It is a beautiful Lake, and the scenery about it is very picturesque, particularly about the Narrows and Lake Gougichin.

Cook s Bay at the southern extremity of the Lake, is about seven miles in length ; about two miles from its termination, a stream called Maskelonge Creek, enters it on its eastern side, and from the Creek to the same point on the opposite side of the Bay, the borders and bed of the Bay are marshy ; this marsh extends southwards along the course of the Holland River for some miles, forming an extensive, nursery for ducks, frogs and mosquitoes. The average depth of Cook s Bay is about five or six fathoms.

Immediately above the mouth of the Bay is a large Island called Snake Island, also occasionally called Muskego Island, from an Indian named Joe Muskego, who claimed it ; and some distance above it, is a smaller Island, called Bird Island. These Islands have been improperly named on many maps ; Snake Island has been called . Muskego Island, and Bird Island has been named Snake Island. Snake Island is situated about three quarters of a mile from the south-east shore of the Lake, and Bird Island about the same distance from the south-west coast. Snake Island contains about three hundred acres, and Bird Island nearly a hundred. The soil of Snake Island is stony, and that of Bird Island gravelly. The timber on both is hardwood, there being very little pine on either.

Snake Island is occupied by a party of Chippewa Indians, who formed one of the three bands settled at Coldwater and the Narrows. At the last report they numbered one hundred and nine, and occupied twelve dwelling houses. They had also, two barns and a school house, in which their children were instructed by a respectable teacher ; they had also, a resident Missionary of the Methodist persuasion. They had at that time, about a hundred and fifty acres under cultivation, and were said to be improving in habits of industry and agricultural skill ; and the Missionary spoke highly of their moral character. The soil of the Island, however, was said to be not well adapted to Indian modes of culture, being too stony. The timber on the Island contains a considerable proportion of maple, and a large quantity of sugar is usually made on it. At the present time there is no Missionary on the Island, but the Indians have still a schoolmaster.

Between Snake Island and the main shore, the water is shallow, there never being more than from five to six feet in the deepest part. Between Snake and Bird Islands, there is deep water. At a distance of two or two and a half miles north-east from Bird Island is a singular shoal; it is about three quarters of a mile in length, and twenty -five or thirty yards in width. It is composed of gravel, and about eighteen inches depth of water on it. It appears to increase very little in size. At, and about Roche s Point, (where is the new settlement called Keswick), the water is generally deep. There was formerly a wharf at this point, but it was carried away by the ice, in eighteen hundred and thirty-nine, and has not since been re-built.

From Roche s Point to Jackson s Point on the south shore is about twelve mites by water. The land is low, timbered principally with hardwood, with a considerable quantity of cedar. The water is sufficiently deep to allow of the steam boat approaching pretty close to the land. About two miles and a half farther east, is Sibbald s Point, between which and the large Island called Graves or Georgina Island, there is shoal water, and the Bay to the south of the Island is bordered by tamarack swamp. To the south and a little east of the Island a long point of land runs out into the lake; this is called De Clot’s Point, and between this Point and the Island, the passage, which is about a mile wide, has a depth of eighteen or twenty feet water. Georgina Island contains about a thousand acres of land, much of which is of good quality. There are two Indian families settled on the Island.”

Wheelwrights and Their Work By R. W. Holden

A wagon wheel consists of four main parts; the tire, the felloes, the spokes, and a hub. The tire was usually made of strip iron fashioned into a circle to be fitted around the circumference of the wheel. With changes in technology steel and rubber tires came into use, though even today iron tires may serve where wagons are still in use (especially among the Amish and Mennonites).

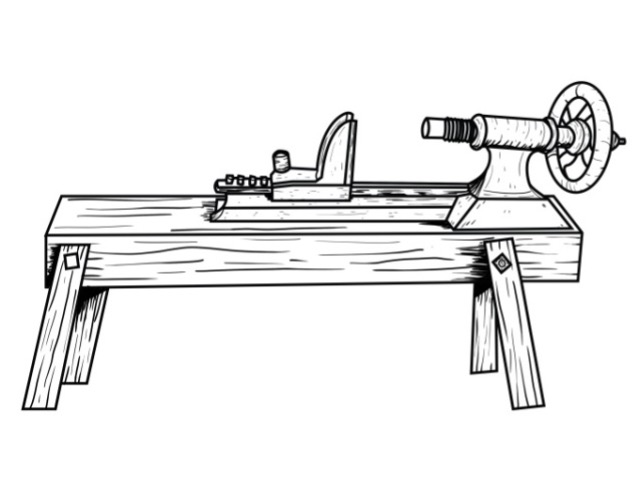

The hub of the wagon wheel is usually made from ash, elm, or a similar type of wood. It would be turned and shaped on a lathe and metal bands would be applied to each side of the hub to strengthen and reinforce it. The hubs would have a boxing or simple bearing inserted and sit on threaded metal axles with heavy duty nuts and washers holding them onto the axle locked in place by a pin. They would be lubricated with tallow or grease. Today hubs may also be made with oil-soaked brass inserts or from metal with sophisticated roller bearings that roll much more freely. The size of the hub would vary with the diameter of the wheel itself and the load it must carry. Wooden hubs would then receive rectangular mortises shaped to take the slightly tapered rectangular tenons made on one end of each spoke. One this was done, the hub would be transferred to a bench that would accommodate tools for cutting the outboard ends of each spoke.

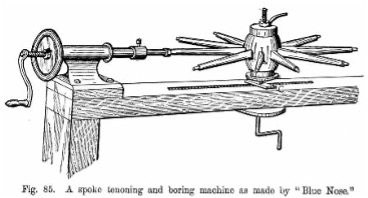

Spokes too varied in length and number with the size of the wheel and the load it must carry. They would begin as long square pieces of wood, usually oak. One end would be shaped into a rectangular tenon and driven into mortises in the hub. The spokes would then be fashioned with a spokeshave to round the edges of the spoke and allow them to move into a slightly dished shape after the metal tire was later applied to the wheel. To finish it off the outboard end would be shaped by a manual cutter into a cone shape. When that was done, the tenon and boring machine would be used to make a round tenon on the outboard end of each spoke.

The felloes are semicircular pieces of wood that make up the outer rim of the wheel. They are made from patterns that vary in size and thickness according to the circumference of each wheel. They would be made on a manual jigsaw, or in later years, a bandsaw. Each felloe was then bored with two round holes carefully positioned to receive the round tenons on two adjacent spokes and are driven into place. As the spokes on the hub diverge from each other, it is necessary to pinch each spoke together with a special tool to ensure the tenons are properly positioned to be driven into each hole.

The wheelwright will then go on to the next pair of spokes and work his way around the wheel. Felloes may be attached to each other with doweling inserted into round mortises on each end of the felloe or be clamped together and a slot cut into the outside of adjoining ends into which a spline is driven. Once the felloes are in place, the wooden parts of the wheel are finished and the wheel is ready for the tire to be applied.

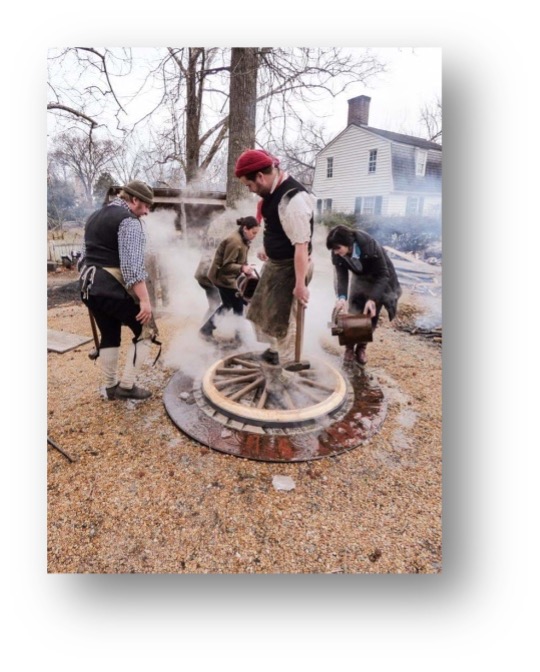

n pioneer times the tire was made from strip iron that varied in width according to the size and width of the tread necessary to carry the desired load. These might often be premade by a blacksmith and made with a very slightly smaller circumference than the wooden wheel rim itself. The tire would then be heated and it would expand sufficiently to exceed the circumference of the rim. It would then be applied to the rim and water would be sprayed onto it to cool the tire forcing it to contract. As this happens the wheel becomes slightly dished in shape as viewed from one end of the tire.

Most all carriage wheels, cannon wheels and wagon wheels have been dished, one of the main reasons the wheel is dished is for strength. Dished wheels were invented by the Romans. From Egyptian times war chariots were built with flat wheels or straight wheels; while this type of wheel was great for fast speed, making a turn with this type of wheel could not be done. If you made a turn with a straight wheel at high speeds it would put pressure on the hub and cause the wheel to fail, so they would have to slow to a stop before making a turn.

The Romans were superior engineers and knew that coming to a stop to make a turn was not the way to win a war. The Romans figured out that putting an iron tire on the wheel while it was hot and let it cool down would pull the wheel together and dish the wheel slightly or cause the center of the hub to be off center not straight. With the wheel dished, it gave the hub more bracing by the spokes unlike the spokes in a straight wheel. The dish would offset the force that would be generated in a turn at a high speed and would allow war chariots to be efficient.

Wagon wheels for the most part, have been made this way since Roman times and into the current century. The wheelwright was an essential tradesman in the days when horse drawn vehicles were king, just as auto mechanics are today, and some are still employed wherever there are people still utilizing wagons and carriages as their main means of conveyance.

Above – a scene from the wheelwright’s shop in colonial Williamsburg. The man on the far left is taking a breather; the one behind is roughing out some new spokes, while the man on the right is cutting mortises into a hub with his chisel. Note the hub top centre mounted for shaping and the patterns for various sizes of fellows hanging on the wall to the right of it. Other tools used are hanging on the wall. The tool just right of the window is used to pull spokes slightly together so the felloes may be driven into their tenons. Beside it and above the felloes patterns is a trammel which would be used to measure the circumference of the finished wooden rim before fitting the appropriately sized tire. ###

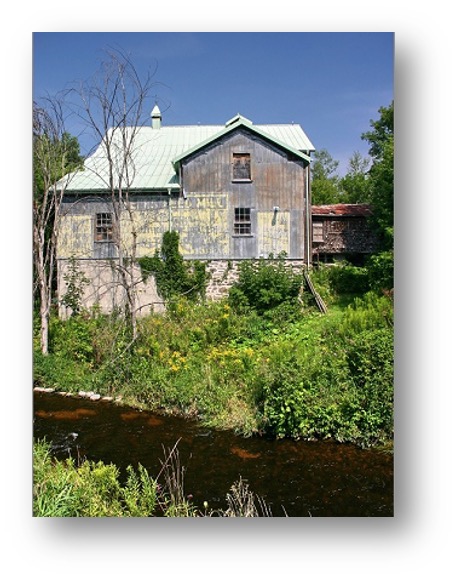

Where in Georgina?

What and where in Georgina is our new mystery location shown on the right?

News & Events

Thanks to the Omicron variant of COVID there is much uncertainty regarding our meetings and events. Therefore we have no meetings or events scheduled and will advise the membership as soon as we have enough information to begin planning them again. As soon as there are any changes, we will advise you all by e-mail. Thank you for your patience and understanding. Be safe and stay well.

Get your 2022 GHS calendar!

We still have a small number of calendars for sale. All proceeds will be used for refurbishing the caboose at the village. Help us with this excellent cause! To purchase your calendar please contact a Board member or Tom Glover at:

905-722-0180 or 905-830-2575

Or e-mail him at btglover@rogers.com

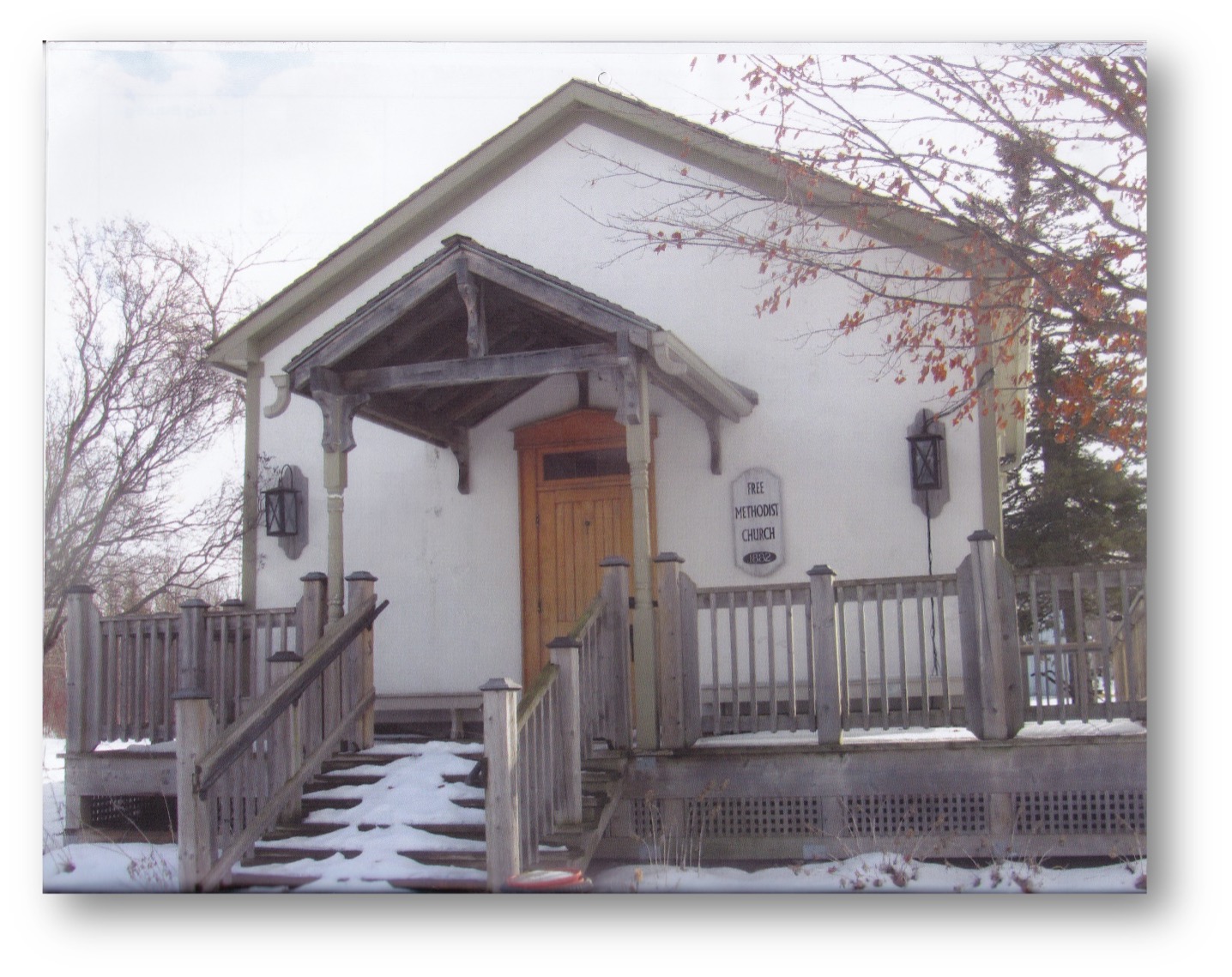

The 2022 calendar features the Elmgrove Methodist Church for the month of January.

The church was built in the early 1880s to serve the communities of Elmgrove (then known as Gum Swamp) and Baldwin and the surrounding area. It was one of the earlier buildings moved to the Pioneer Village in the 1970s by the Historical Society.